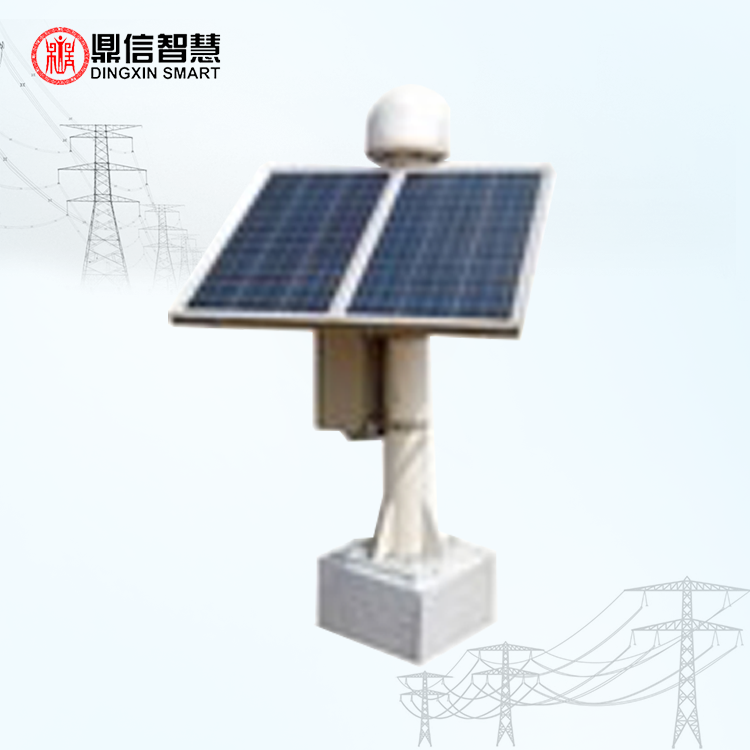

Beidou Displacement and Deformation Monitoring and Early Warning System for High speed Railway

model:DX-WPS100-WY

1、 Demand analysis

With the continuous expansion and improvement of domestic high-speed railway network and the rapid development of municipal engineering, there are more and more cross projects between the two. The high-speed railway in operation has very high requirements on the smoothness of the line, and the safety, design and construction of the underpass project have high requirements and difficulties. Construction under high-speed railway landslides and bridges will have many adverse effects on high-speed railway operation. Once an accident occurs, the consequences will be unimaginable. Therefore, it is necessary to put an end to the occurrence of events that affect the safe operation of the railway. In order to avoid or reduce the impact of construction on high-speed railway operation, it is necessary to analyze and evaluate the impact on the project before construction. At present, there is no technical specification for undercrossing high-speed railway engineering at home and abroad to guide engineering design, construction and monitoring. Therefore, the construction and use of mountain slopes and undercrossing structures have become one of the main factors affecting the safety of high-speed railway operation.

2、 Working principle

The deformation monitoring and slope monitoring of high-speed railway bridges include the monitoring of transverse, longitudinal horizontal displacement and vertical displacement of piers and abutments. The automatic monitoring method should be adopted. The automatic monitoring system is mainly used for real-time online monitoring, including data acquisition system, data communication system and data analysis system. The high-speed railway GNSS displacement and deformation monitoring system can be divided into four layers: perception layer, network layer, platform layer and application layer.

Perception layer: real-time induction of the status of high-speed railway monitoring parameter sensors, such as surface displacement, deep displacement, seepage flow, rainfall, cracks, supporting structures, groundwater level, soil moisture content, soil pressure, surface displacement monitors, video surveillance cameras and other front-end sensing equipment;

Network layer: It supports data communication, two-way communication between up and down, wireless cellular network, SMS, Beidou, PSTN, ultrashort wave, ZigBee and other communication methods. The sensing device M21F2 can be sent upstream to the monitoring control center platform through the communication mode of the monitoring and early warning platform.

Platform layer: integrate the equipment and system functions of each layer, issue the command from the platform to the front-end sensor through signal connection, upload the collection, processing, storage and analysis of monitoring data, and link the major front-end monitoring equipment in real time.

Application layer: open information release channels, and display information data and early warning information in real time.

3、 Product features

(1) Basic configuration of Beidou displacement and deformation monitoring: main control unit, Beidou displacement and deformation monitoring unit, communication unit, power supply unit, installation bracket and auxiliary materials;

(2) 24-hour real-time monitoring: fully automated online monitoring of railway subgrade settlement, displacement, deformation, stress, environment, bridge vibration, etc., to grasp the safety status of the overall construction/operation of the railway in real time.

(3) Multi level early warning: when data is abnormal, the system will trigger the corresponding three-level alarm mechanism, and notify users of the time in the form of SMS, fax, broadcast, etc.

(4) Emergency plan handling: corresponding handling methods are directly extracted from the expert database, and personnel intervention, railway blockade and other measures are taken in time to eliminate potential safety hazards in the bud.

(5) Research on structural damage mechanism: macro analysis of structural damage mechanism, research on structural deformation and damage trend, induction and deduction.

(6) Reference basis: the storage of monitoring data provides an analogy basis for the design and construction of similar projects in the future.

(7) Formation of industry standards: develop a safety evaluation standard system suitable for structural health monitoring, and form industry standards and specifications.

4、 Product parameters

Serial No | category | project | technical parameter |

| 1 | Overall performance | Complete machine configuration | Main control unit, Beidou displacement and deformation monitoring, communication unit, power supply unit, installation support and auxiliary materials; |

Overall quality | Less than 30KG (including solar panel and support) | ||

texture of material | Stainless steel body+hot galvanized support | ||

Beidou displacement and deformation monitoring unit | *Observation frequency | Receive multiple navigation satellite system BDS (B1/B2), GPS (L1/L2) | |

*Measurement accuracy | Horizontal accuracy: ± 2.5 mm+0.5 ppm; Vertical accuracy: ± 5 mm+0.5 ppm; | ||

Signal receiving sensitivity | ≤-133dBm | ||

Power Supply | Power input port | ||

antenna | One GNSS antenna interface, socket type TNC | ||

*Remote control | Remote upgrade, remote reset and remote parameter setting | ||

Number of Beidou modules | Support 4; | ||

3 | Beidou antenna unit | *Signal tracking | Can receive GPS satellite L1 L2 L5 signal, GLONASS satellite L1 L2 signal, Beidou satellite B1 B2 B3 signal, Galileo satellite signal |

Phase center index | The phase center stability is better than 1mm, and the phase center deviation (elevation 20 °) is less than 1.5mm (1 σ)。 | ||

Polarization mode | Right-handed circular polarization | ||

Antenna beam | Azimuth angle: 0 °~ 360 °, pitch angle: 5 °~ 90 ° | ||

Axial ratio | ≤2dB(elevation90°)≤4dB(elevation20°~90°) | ||

VSWR | ≤1.5(50Ω) | ||

4 | Communication unit | communication mode | All Netcom 4G/5G/WIFI wireless transmission |

Data security | VPN dedicated channel can be used for communication with the master station, and encryption transmission is optional。 | ||

Access protocol | Accessible to railway monitoring platform | ||

5 | Power supply unit | Battery capacity | 100Ah/12V, lithium iron phosphate battery, high reliability battery |

Solar panel power | 180W/18V, single crystal silicon high-efficiency solar panel | ||

Power supply duration | The power supply requirement that the device can operate normally for 15 days without continuous illumination. | ||

Other parameters | work environment | Working temperature: - 40~+70 ℃; Relative humidity: 5-99% RH | |

Overall service life | More than 8 years | ||

Degree of protection | IP67 |